Finding, reusing and managing parts

Engineers waste an average of 70% of their time searching for, configuring, and unnecessarily creating new parts. As a result, thousands of hours are spent each year on work that make only a small contribution to added value. In addition, each newly introduced component generates enormous additional costs. This inefficient approach makes it difficult to develop innovative products and bring them quickly to market.

High cost and time savings

Finding and managing parts

Interfaces to many systems

“I just want to develop”, the engineer said.

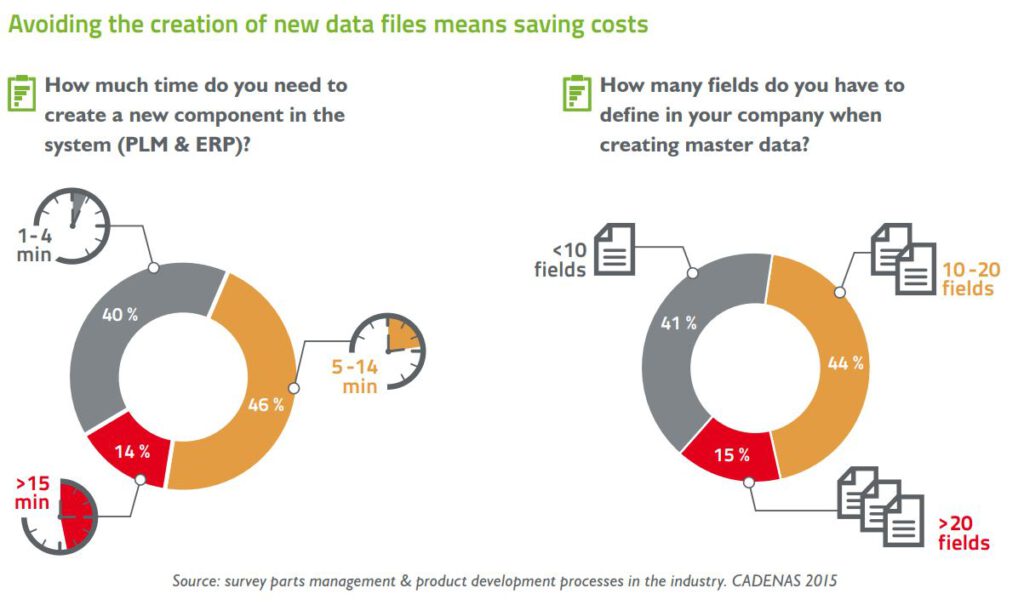

Even though master data is becoming increasingly important as a result of digitalization, companies still regard its creation and maintenance as an annoying obligation that needs to be handled. Know-how is often lacking. Employees, who actually have other tasks to fulfil, must also take care of master data. The result is often poor data quality from which subsequent processes suffer.

Here is an example from construction: Instead of the engineer fully concentrating on the development of innovative products, to a large extent, his or her workday probably consists of rather unattractive activities such as creating master data. Not only is data creation an extreme annoyance, it also takes up considerable time and financial resources.

Common problems encountered

- PLM and ERP systems are bursting with parts.

- Systems are full of duplicates and outdated parts.

- It is difficult to find the right parts.

- No standardization, master data is chaotic.

- Several CAD systems are used in the company.

- The purchasing department has no influence on the parts selection.

Save a lot of time and money through strategic parts management

In this short video, we will show you how you and your company can overcome these obstacles and create more room for the development of innovative products.

PARTsolutions live!

In a free 30-minute live demo, our experts will guide you through our software – so you can see for yourself how easy it is to use and how intuitive the user interface is

Arrange a demo appointment

Reusing parts instead of creating new parts

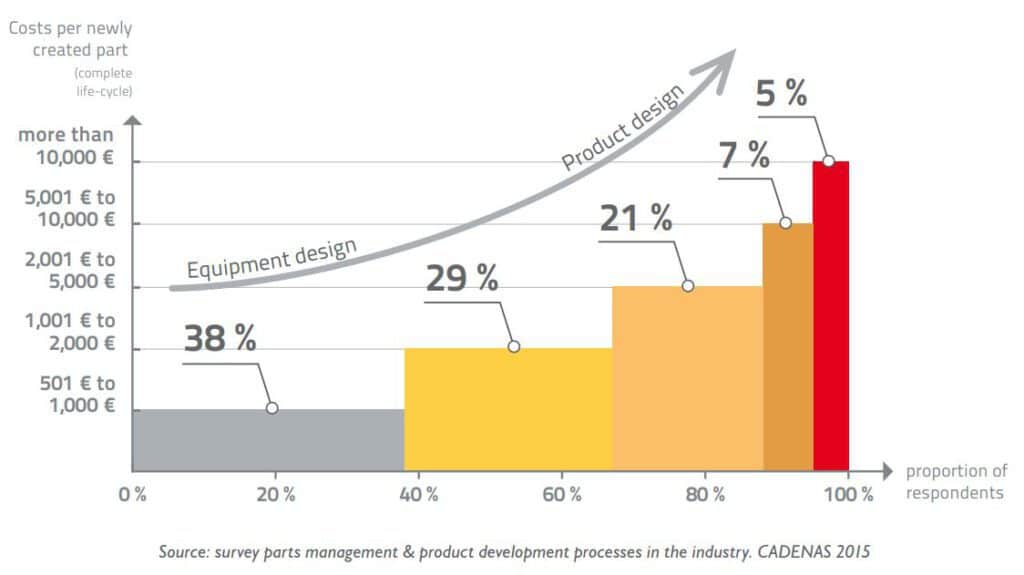

Each new part created incurs additional costs across the entire lifecycle which go far beyond the mere expense of creating data.

How high do you estimate the total lifecycle costs of a component in your company?

(data creation, warehousing, fixed capital, end-of-life replacement, etc.)

Advantages for…

engineers

- more than 850 CAD manufacturer catalogs available

- intelligent 3D CAD models in native CAD formats

- intelligent search methods for components

- extensive metadata & kinematics

- seamless integration into CAD and PLM

standardization

- Perfect master data for CAD, PLM and ERP ensure reduced variety of parts.

- Find existing parts in the PLM system and avoid duplicates in your database.

- Classification support (ECLASS and Classification 2.0)

purchasing

- PURCHINEERING (cooperation between purchasing and engineering)

- Determine preferred parts and suppliers.

- Definition of a release process for new parts to prevent unnecessary variety of parts

Accurate creation of new part master data

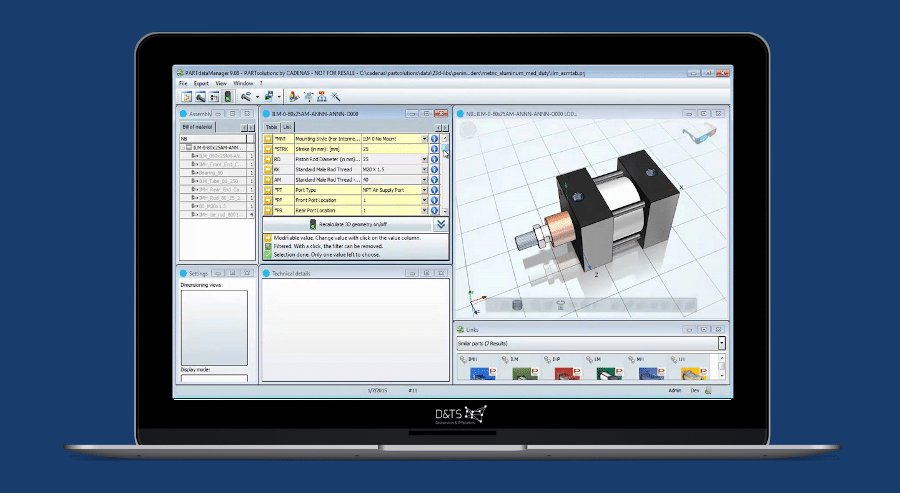

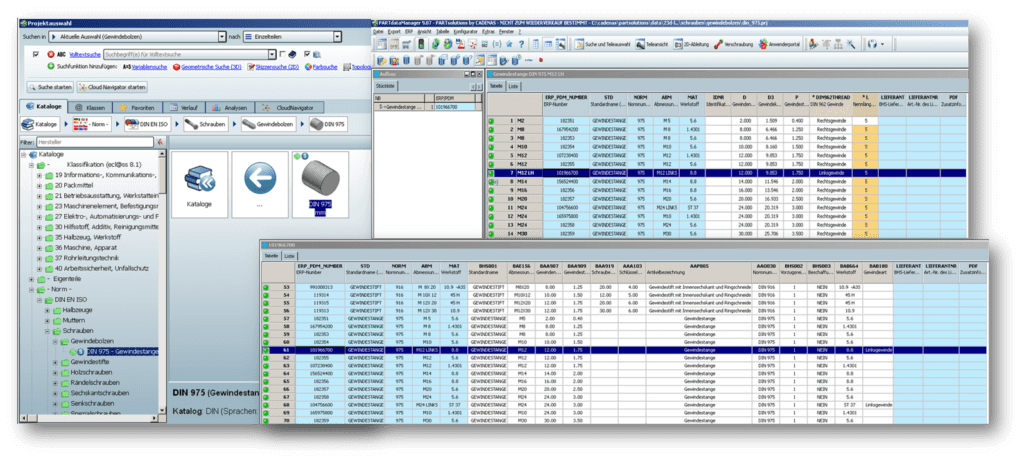

More than 850 manufacturer catalogs: Optimal basis for your master data

PARTsolutions offers engineers direct access to more than 850 certified CAD parts catalogs of well-known international manufacturers. The extensive standard and purchased parts library of the strategic parts management complements your database with detailed parts information. This ensures a flawless, organized database with correct manufacturer designations and order numbers significantly reducing the subsequent search effort for suitable components.

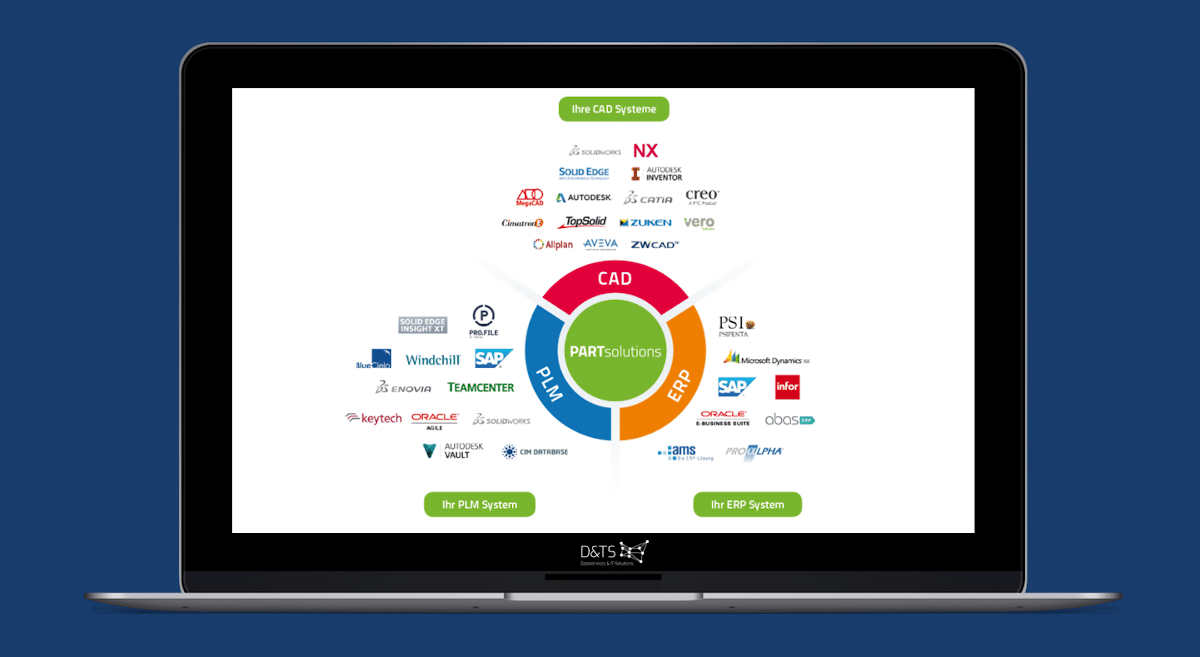

Open to all systems

No matter which CAD, PLM or ERP systems are already used in your company, PARTsolutions by CADENAS is open to all systems.

Strategic parts management brings together all the relevant information from the various solutions on a single platform.

Contact us now

Classification of your drawing/individual parts

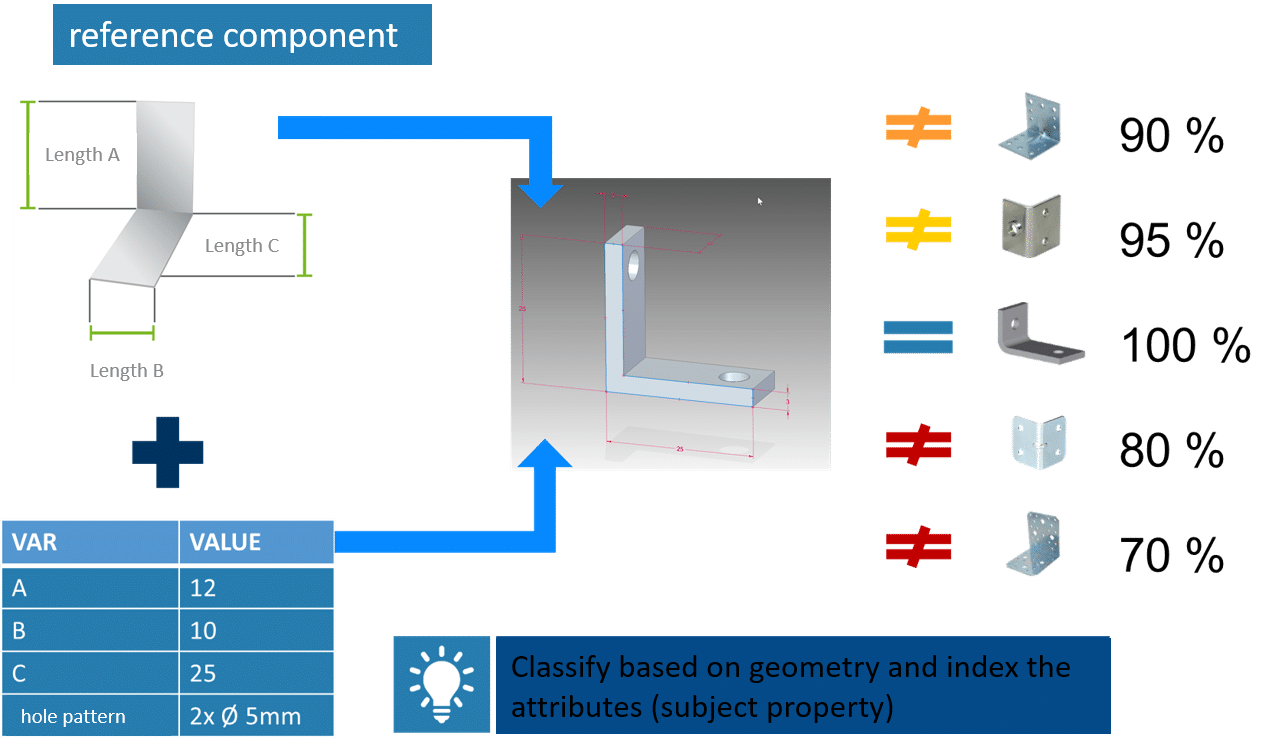

Classification 2.0 – geometric similarity search for 3D models

Classified product master data enables engineers and purchasers to efficiently find required components. However, most companies struggle to successfully implement classification/standardization topics for product master data. Generally applicable classification systems, such as ECLASS or ETIM, are well-suited for standard components such as standard and purchased parts. However, they are oftentimes unsuitable for drawing parts. In addition, a correct, manual assignment of parts to an existing classification system is very time-consuming and costly. Another issue is the subjective decisions of employees on how to correctly classify a product. Enormous deviations may occur. With Classification 2.0 in PARTsolutions, the system automatically searches for the parametric reference model (3D). For this, we only need your native design drawings. This means that time-consuming manual preparatory work is no longer necessary and subjective decisions are irrelevant.

In Classification 2.0, parametric reference models are stored for each class. For example, if an L-angle with certain dimensions is required, the system searches for parts that are geometrically similar to the parametric reference model. With classification 2.0, in addition to the component class (e.g., L-angle), the number and size of the holes must also be taken into account. Using a topology search, the system easily finds exactly the components with the necessary holes for your design in your database.

D&TS will be happy to advise you, from implementation to customer service.Classification of standard and purchased parts

Classification systems and ECLASS

D&TS will advise you on the most suitable standard classification system for your company or will also support you in building your own classification system. We classify your standard and purchased parts and visualize them in PARTsolutions. Through classification, you increase reuse in “C-parts” and reduce the administrative effort for management, approval and processing. In the long term, this will reduce the new creation of parts in your system and, by bundling suppliers, your procurement costs. D&TS has successfully classified material master data according to the ECLASS standard in numerous projects with renowned mechanical engineering companies.

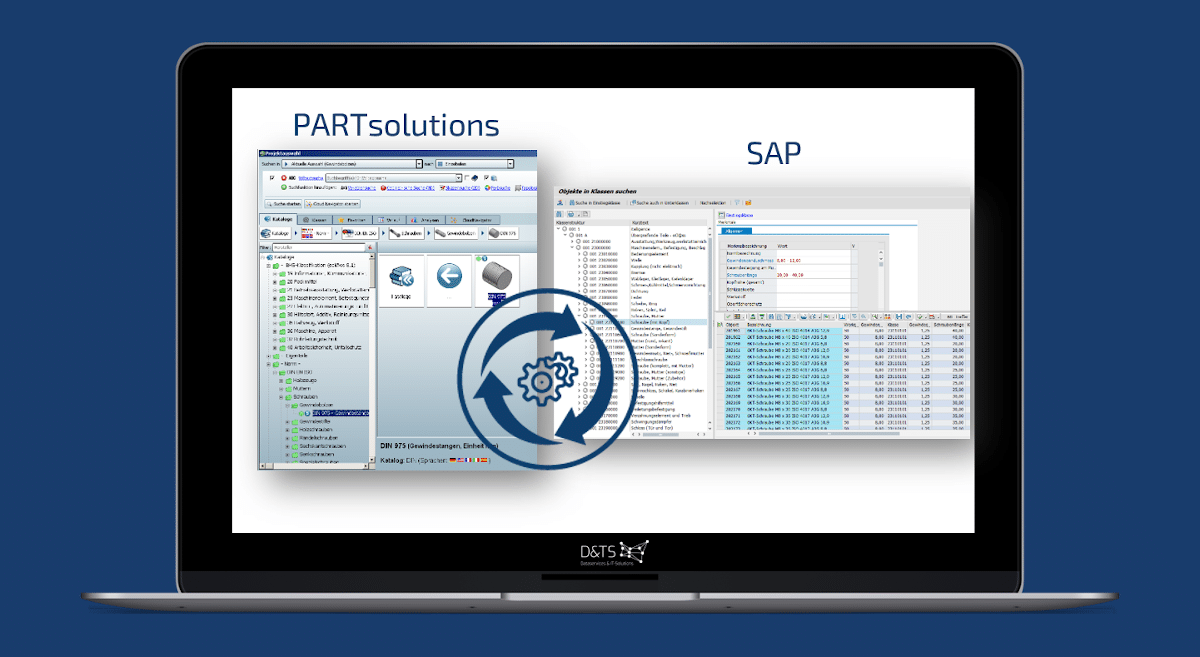

Perfect data reconciliation

Synchronization between PARTsolutions and SAP

Data kept in sync is one of the most important building blocks. The ClassCOCKPIT Synchro module synchronizes your material data, classification structures and content between two systems. It enables automated success control and offers specific options in terms of export quantity or the export period.

Contact us now

D&TS builds a classification with you – whether it is ECLASS, ETIM or self-classification.

Our consultants look forward to speaking with you

Please feel free to call us or simply send us your request by mail.